Membrane Cleaners

King Lee Technologies started manufacturing specialty RO/NF membrane cleaners over 40 years ago. Since then, we have continued to develop effective membrane cleaners used in a wide variety of applications. These include groundwater, surface water, seawater and reuse applications.

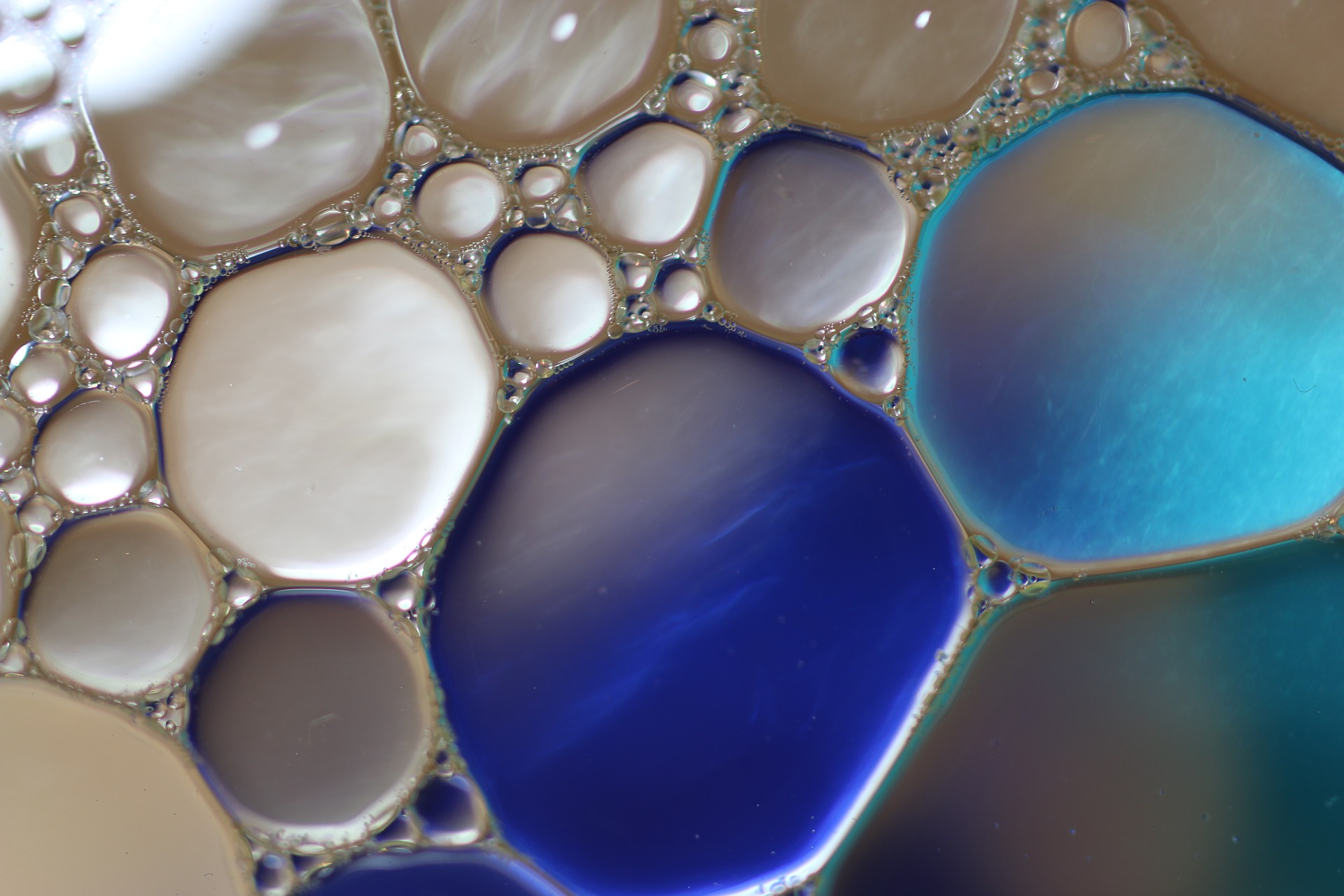

Even with effective pretreatment, membranes will eventually begin to scale or foul. Depending on the degree and type of fouling, generic low and high pH cleaners may not fully clean off scale and foulants. Thus, residual residue could act as a hub attracting more scale and foulants resulting in a quicker fouling rates resulting in the need to clean more frequently. King Lee offers a variety of membrane cleaners to meet your specific needs. We offer our KL series powder cleaners for cost effectiveness and Diamite series liquid cleaners for ease of use.

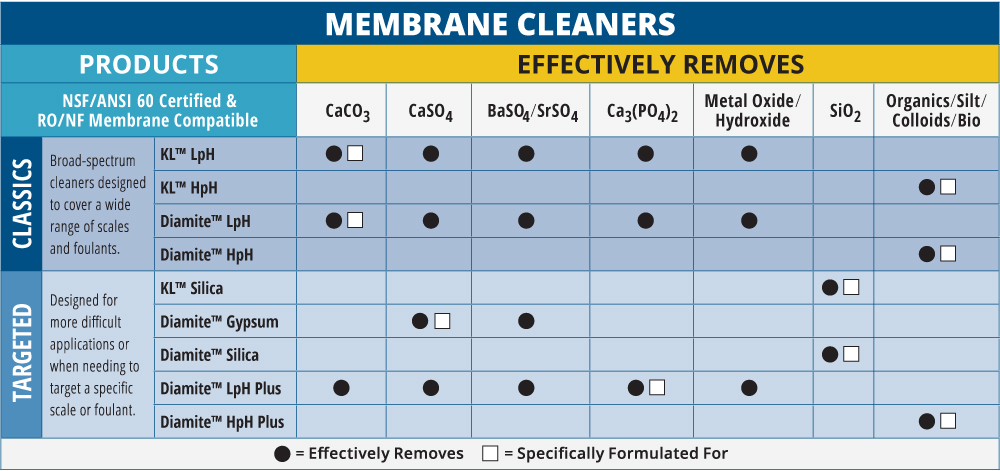

Classics: Broad spectrum cleaners designed to cover a range of scales and foulants.

Targeted: Designed for tougher applications or which need a targeted cleaner.